G Sand is manufactured sand, obtained from specific hard rock (granite) using the state-of-the-art International technology. G Sand is cubical in shape and is manufactured using international technology like High Carbon steel hit rock and then ROCK ON ROCK process which is synonymous to that of natural process undergoing in river sand formation.

Why G Sand ?

Sand is widely used in highway construction, concrete making, etc. As the field of industry application gradually expanded, the gradual application of natural sand work more and failed to keep pace with the various sectors of modern world development needs. Historically, a large percentage of sand has been produced from alluvial deposits. However we are now experiencing a global shortage of natural sand, and environmental pressures, costs and a shortage of this type of deposit has necessitated the manufacture of sand from quarried material.

One of the problems often experienced with natural sand is the presence of contaminants, which can be very difficult to remove. These contaminants may be silt, organic matters and sometimes, harmful chemicals, such as sulphates and chlorides, all of which can have significant detrimental effects on the performance of structural concrete. Manufactured sand, on the other hand, comes directly from good quality virgin rock, and thus very few, if any contaminants are present.

The main defect of river sand is that it contains various contaminants like mud, clay, organic wastes, sulphite, chloride etc, which are very difficult to separate from it. These residual contaminants weaken concrete. Since G sand ( Graded Sand) is manufactured from clean and qualitative rocks, it is free from contaminants.

Triangle Homez Supports this type of new Generation building materials

Advantages of G Sand

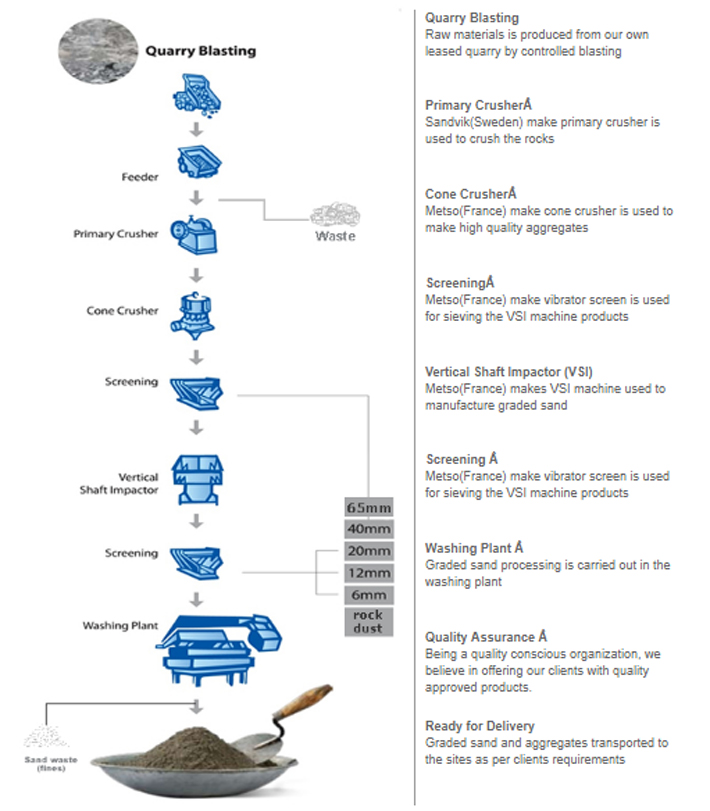

1. Manufacturing high quality G Sand with advanced technology Machines, Imported from France ,Sweden and Newzeland

2. Price of G Sand which is almost half the river sand

3. Two ranges of G Sand available in market

a. 0.15 – 3 mm – Plastering sand

b. 0.15 x 4.75 mm – Concrete sand

4. Available throughout the year with a manufacturing capacity of 2000 tonnes per day

5. No price inflation during Monsoon season.

6. G Sand is Eco – Friendly, Easy to use and Even Dimension better than River Sand.

7. No need for Screening

8. No Wastage, Clay Free and Economically better than River Sand.

9. Water Washed Slit Free and 100% Purified, Better Bonding Strength with Cement

10. Less curing time than River Sand.

11. Instant delivery by company owned fleet or market truck (as per requirement & distance)